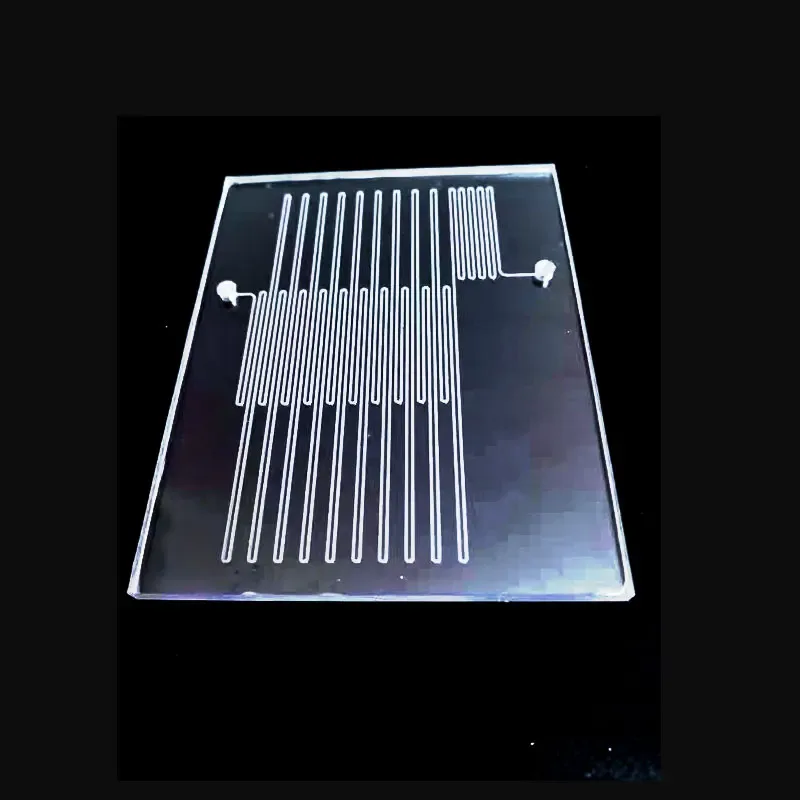

Cnc Route Acrylic Microfluidic Chips Machining Acrylic Chip

Product Overview

collection is made up of Microfluidic Chip materials. As we focus on the improvement of the quality, this product has been manufactured with high quality and stable performance. Microfluidic Chip of can be used in various scenarios in different fields. Based on professional design & production capacity, provides a complete OEM service system.

1. The same flow channel can realize variable depth structure

2. It can realize PMMA+PMMA bonding, glass + glass bonding, and good air tightness ensures that there is no leakage

3. It can be directly processed into convex and concave microstructure units on silicon material, PMMA,photosensitive resin, quartz glass, metal and other materials.

In recent years, our company has made many improvements and innovations to equipment and tools based on the principles of optics and mechanics.Breaking through the limitations of traditional technology and materials, it has successfully solved the technical problems of traditional CNC machining applied to microfluidic molds.After processing, without any surf- ace treatment, the mold effect with a smoothfinish within 20nm can be achieved.

We are good at micro processing of small tools, combining nano processing technology with special processing technology and equipment,Ingenuity in the field of chip mold and manufacturing.

Various optical cold processing methods: drilling, edging, polishing. Grooving, cutting

The chipping edge is less than 0.02 mm, the positioning accuracy is higher than 3 microns, and various thickness dimensions and arcs can be processed.

Company Advantages

appears to rise in the Microfluidic Chip market. Our company has a strong and experienced technical development team. The team is able to offer diverse product solutions on customization, development, and product upgrade. Our sustainable development plan is how we fulfill our social responsibility. We have formulated and executed many plans to reduce carbon footprints and pollution to the environment. Check it!

If you want to know more details of our products, please contact us. We are looking forward to cooperating with you!

ABOUT US