From concept to production, KONLIDA works closely with clients to optimize material selection, shape, and performance—ensuring seamless integration in electronics, medical, and industrial systems.

Conductive Silicone Rubber

What is Conductive Silicone Rubber?

Conductive silicone rubber combines the superior environmental sealing and thermal stability of silicone elastomers with the electrical conductivity of metal-filled compounds. By dispersing conductive particles (e.g., silver-plated aluminum, nickel-coated graphite) within a silicone or fluorosilicone matrix, this material simultaneously delivers EMI/RFI shielding, electrical grounding, and robust sealing in demanding environments.

Core Features & Benefits

- Electrical Conductivity — Achieves from semi-conductive levels to highly conductive states by adding fillers such as silver, nickel, carbon or gold.

- Thermal Stability — Operates reliably across wide temperature ranges (commonly –55 °C to +200 °C or higher in specialized trims).

- Flexibility & Elasticity — Maintains pliability under mechanical stress and vibration, essential for gasket and sealing applications.

- Chemical & Environmental Resistance — Resists oils, solvents, UV, ozone and moisture, ensuring long-term durability.

- Formability & Integration — Supports sheets, extrusions, die-cut parts or molded profiles enabling versatile manufacturing.

Types of Electrically Conductive Silicones

Engineers have a wide array of electrically conductive silicones to choose from, depending on the application and performance requirements.

The main types include:

- EMI/RFI Shielding Materials: Silicones filled with conductive particles like nickel-coated graphite or silver are used for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding in electronic devices.

- Thermal Interface Materials (TIMs): These materials combine thermal and electrical conductivity, serving as interfaces between heat-generating components and heat sinks or spreaders.

- Conductive Elastomers: These flexible materials are often used in gaskets, seals, and keypads. Their combination of electrical conductivity and mechanical resilience makes them suitable for harsh environments.

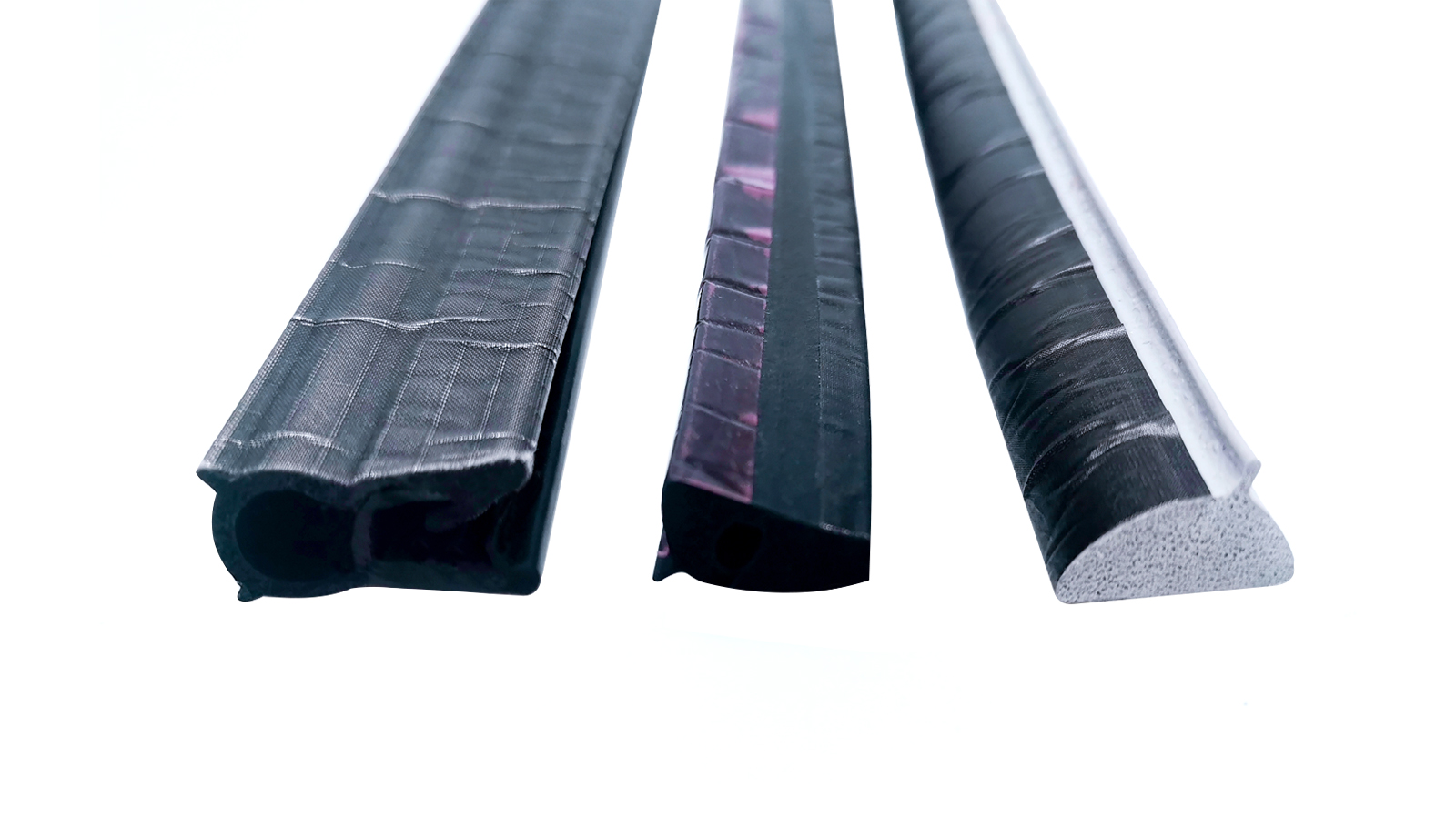

- Extruded Conductive Silicone Strips: Continuous lengths of filled silicone for ribbon shielding, cable wrap, or frame grounding.

- Die-Cut Gaskets & Profiles: Pre-cut or custom-extruded silicone seals combining conductive fillers and sealing functionality for enclosures.

- Carbon-Based Conductive Silicones: These are lightweight and cost-effective alternatives for applications requiring moderate conductivity, such as antistatic coatings and ESD (electrostatic discharge) protection.

Applications

- EMI/RFI Shielding Gaskets: For electronic housings and enclosure seams.

- Chassis and Enclosure Seals: Provides grounding and environmental sealing.

- Connector and Interface Pads: Ensures stable electrical contact and signal grounding.

- Display and Touch Panel Frames: Prevents EMI leakage and static buildup.

- PCB Ground Pads: Replaces metal contacts for consistent conductivity.

- Battery Pack Sealing: Offers conductive and heat-resistant protection.

- Waveguide and Filter Seals: Ensures low-resistance shielding performance.

- Custom Molded or Extruded Parts: Designed for complex sealing and grounding needs.

Specifications/Data

|

Unit | Specification | Test Standard | |

| Materials | - | Silicone Rubber, Fluorosilicone Elastomer | - | |

| Coatings | - | Al+Ag, Ni+Ag, Cu+Ag, Al+Ni, Ni+C, Glass+Ag | - | |

| Density | g/cm³ | 1.9 (Customizable) | ASTM D792 | |

| Volume Resistivity | Ohm-cm | 0.1 (Customizable) | MIL-DTL-83528C | |

| Hardness | Shore A | 65 (Customizable) | ASTM D2240 | |

| Tensile Strength | PSI | 200 | ASTM D412 | |

| Elongation | % | 150 | ASTM D412 | |

| Tear Strength | PPI | 30 | ASTM D624 | |

| Working Temperature | ℃ | -55~+170 | ASTM D1329 | |

| Shielding Efficiency | dB | 500MHz/ 100、2GHz/100、10GHz/100 | MIL-DTL-83528C | |

Custom Solutions

KONLIDA provides fully customized conductive silicone solutions—combining electrical performance, sealing reliability, and precision engineering to meet diverse industry needs.

Get in touch with us

Please feel free to reach out to us with any questions, comments, or concerns. You can contact our customer support team at phone number or email address.

We are here to assist you in any way we can. Thank you for choosing to connect with us.

What is Conductive Silicone Rubber?

Conductive silicone rubber combines the superior environmental sealing and thermal stability of silicone elastomers with the electrical conductivity of metal-filled compounds. By dispersing conductive particles (e.g., silver-plated aluminum, nickel-coated graphite) within a silicone or fluorosilicone matrix, this material simultaneously delivers EMI/RFI shielding, electrical grounding, and robust sealing in demanding environments.

Core Features & Benefits

- Electrical Conductivity — Achieves from semi-conductive levels to highly conductive states by adding fillers such as silver, nickel, carbon or gold.

- Thermal Stability — Operates reliably across wide temperature ranges (commonly –55 °C to +200 °C or higher in specialized trims).

- Flexibility & Elasticity — Maintains pliability under mechanical stress and vibration, essential for gasket and sealing applications.

- Chemical & Environmental Resistance — Resists oils, solvents, UV, ozone and moisture, ensuring long-term durability.

- Formability & Integration — Supports sheets, extrusions, die-cut parts or molded profiles enabling versatile manufacturing.

Types of Electrically Conductive Silicones

Engineers have a wide array of electrically conductive silicones to choose from, depending on the application and performance requirements.

The main types include:

- EMI/RFI Shielding Materials: Silicones filled with conductive particles like nickel-coated graphite or silver are used for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding in electronic devices.

- Thermal Interface Materials (TIMs): These materials combine thermal and electrical conductivity, serving as interfaces between heat-generating components and heat sinks or spreaders.

- Conductive Elastomers: These flexible materials are often used in gaskets, seals, and keypads. Their combination of electrical conductivity and mechanical resilience makes them suitable for harsh environments.

- Extruded Conductive Silicone Strips: Continuous lengths of filled silicone for ribbon shielding, cable wrap, or frame grounding.

- Die-Cut Gaskets & Profiles: Pre-cut or custom-extruded silicone seals combining conductive fillers and sealing functionality for enclosures.

- Carbon-Based Conductive Silicones: These are lightweight and cost-effective alternatives for applications requiring moderate conductivity, such as antistatic coatings and ESD (electrostatic discharge) protection.

Applications

- EMI/RFI Shielding Gaskets: For electronic housings and enclosure seams.

- Chassis and Enclosure Seals: Provides grounding and environmental sealing.

- Connector and Interface Pads: Ensures stable electrical contact and signal grounding.

- Display and Touch Panel Frames: Prevents EMI leakage and static buildup.

- PCB Ground Pads: Replaces metal contacts for consistent conductivity.

- Battery Pack Sealing: Offers conductive and heat-resistant protection.

- Waveguide and Filter Seals: Ensures low-resistance shielding performance.

- Custom Molded or Extruded Parts: Designed for complex sealing and grounding needs.

Specifications/Data

| Unit | Specification | Test Standard | ||

| Materials | - | Silicone Rubber, Fluorosilicone Elastomer | - | |

| Coatings | - | Al+Ag, Ni+Ag, Cu+Ag, Al+Ni, Ni+C, Glass+Ag | - | |

| Density | g/cm³ | 1.9 (Customizable) | ASTM D792 | |

| Volume Resistivity | Ohm-cm | 0.1 (Customizable) | MIL-DTL-83528C | |

| Hardness | Shore A | 65 (Customizable) | ASTM D2240 | |

| Tensile Strength | PSI | 200 | ASTM D412 | |

| Elongation | % | 150 | ASTM D412 | |

| Tear Strength | PPI | 30 | ASTM D624 | |

| Working Temperature | ℃ | -55~+170 | ASTM D1329 | |

| Shielding Efficiency | dB | 500MHz/ 100、2GHz/100、10GHz/100 | MIL-DTL-83528C | |

Custom Solutions

KONLIDA provides fully customized conductive silicone solutions—combining electrical performance, sealing reliability, and precision engineering to meet diverse industry needs.

Get in touch with us

Please feel free to reach out to us with any questions, comments, or concerns. You can contact our customer support team at phone number or email address.

We are here to assist you in any way we can. Thank you for choosing to connect with us.

Expert In Custom Solutions For More Efficient Electromagnetic Shielding Components

no data

Mob:+86 189 1365 7912

Tel: +86 0512-66563293-8010

Email: sales78@konlidacn.com

Address: 88 Dongxin Road, Xukou Town, Wuzhong District, Suzhou City, Jiangsu Province, China

ABOUT US

Copyright © 2026 KONLIDA | Sitemap