What is Polyimide Film ?

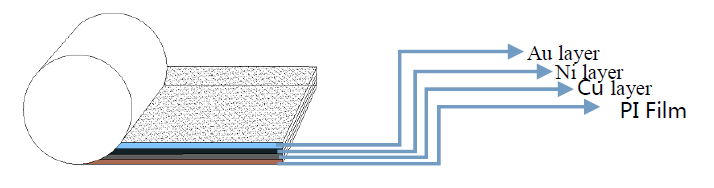

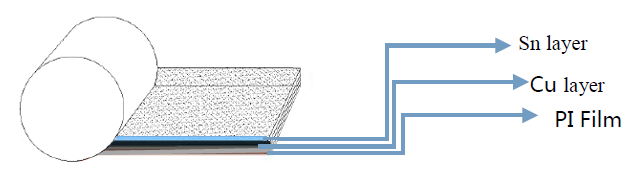

Conductive Polyimide Film combines the exceptional thermal, mechanical, and chemical stability of standard PI film with enhanced electrical conductivity. By depositing metal layers such as copper, nickel, or gold onto the PI surface, the film achieves superior EMI shielding and grounding performance while maintaining flexibility and durability.

It is widely used in automotive electronics, communication devices, computer systems, and automatic control equipment.

KONLIDA Polyimide Film Solutions

Core Features & Benefits

Excellent EMI Shielding: Provides effective electromagnetic protection for sensitive circuits.

High Flexibility: Maintains stability and conductivity even under bending or vibration.

Thermal Resistance: Performs reliably from -40°C to 200°C, suitable for harsh environments.

Chemical & Moisture Resistance: Withstands corrosion, humidity, and solvents.

Lightweight & Easy to Process: Ideal for die-cutting, laminating, or integration into flexible assemblies.

Cost-Effective Performance: Optimized coating composition for superior value.

Typical Applications

- Flexible Circuits: Stable substrate for FPC and fine-pitch interconnects.

- EMI Shielding: Conductive layer for electronic enclosures and devices.

- Sensors: Flexible base for temperature and pressure sensors.

- Displays: Used in foldable and transparent display panels.

- Battery Insulation: Heat- and voltage-resistant layer in battery packs.

- Cables & Connectors: Conductive insulation for grounding and EMI control.

- Heater Films: Applied in thin heating and thermal control systems.

- Adhesive Tapes: High-temperature masking and conductive bonding films.

Specifications/Data

| Gold-plated PI Film | ||

|

||

| Materials | Polyimide+Cu+Ni+Au | |

| Thickness | 27μm (Customized) | |

| Surface Resistance | ≤0.06Ω/inch² | |

| Working Temperature | -40 ~ 200℃ | |

| Shielding Efficiency | 70-100(10MHz-1GHz) | |

| Tin-plated PI Film | ||

|

||

| Materials | Polyimide+Cu+Sn | |

| Thickness | 25μm (Customized) | |

| Surface Resistance | ≤0.06Ω/inch² | |

| Working Temperature | -40 ~ 150℃ | |

| ROHS Requirement | Halogen-free | |

What is Polyimide Film ?

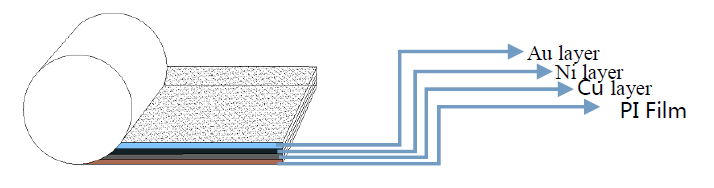

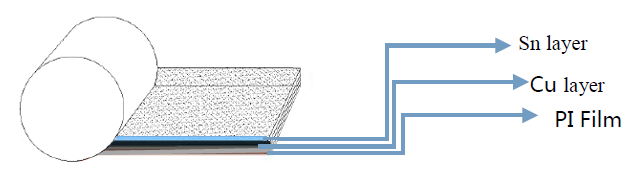

Conductive Polyimide Film combines the exceptional thermal, mechanical, and chemical stability of standard PI film with enhanced electrical conductivity. By depositing metal layers such as copper, nickel, or gold onto the PI surface, the film achieves superior EMI shielding and grounding performance while maintaining flexibility and durability.

It is widely used in automotive electronics, communication devices, computer systems, and automatic control equipment.

KONLIDA Polyimide Film Solutions

Core Features & Benefits

Excellent EMI Shielding: Provides effective electromagnetic protection for sensitive circuits.

High Flexibility: Maintains stability and conductivity even under bending or vibration.

Thermal Resistance: Performs reliably from -40°C to 200°C, suitable for harsh environments.

Chemical & Moisture Resistance: Withstands corrosion, humidity, and solvents.

Lightweight & Easy to Process: Ideal for die-cutting, laminating, or integration into flexible assemblies.

Cost-Effective Performance: Optimized coating composition for superior value.

Typical Applications

- Flexible Circuits: Stable substrate for FPC and fine-pitch interconnects.

- EMI Shielding: Conductive layer for electronic enclosures and devices.

- Sensors: Flexible base for temperature and pressure sensors.

- Displays: Used in foldable and transparent display panels.

- Battery Insulation: Heat- and voltage-resistant layer in battery packs.

- Cables & Connectors: Conductive insulation for grounding and EMI control.

- Heater Films: Applied in thin heating and thermal control systems.

- Adhesive Tapes: High-temperature masking and conductive bonding films.

Specifications/Data

| Gold-plated PI Film | ||

|

||

| Materials | Polyimide+Cu+Ni+Au | |

| Thickness | 27μm (Customized) | |

| Surface Resistance | ≤0.06Ω/inch² | |

| Working Temperature | -40 ~ 200℃ | |

| Shielding Efficiency | 70-100(10MHz-1GHz) | |

| Tin-plated PI Film | ||

|

||

| Materials | Polyimide+Cu+Sn | |

| Thickness | 25μm (Customized) | |

| Surface Resistance | ≤0.06Ω/inch² | |

| Working Temperature | -40 ~ 150℃ | |

| ROHS Requirement | Halogen-free | |

ABOUT US