Quick Overview

Gear& Fastener is manufactured exactly according to your specifications by using the most advanced technology and equipment. We make use of guaranteed raw material that is procured for trusted vendors to guarantee the quality of this product. has gone far ahead in the Gear& Fastener industry for the finest quality service.

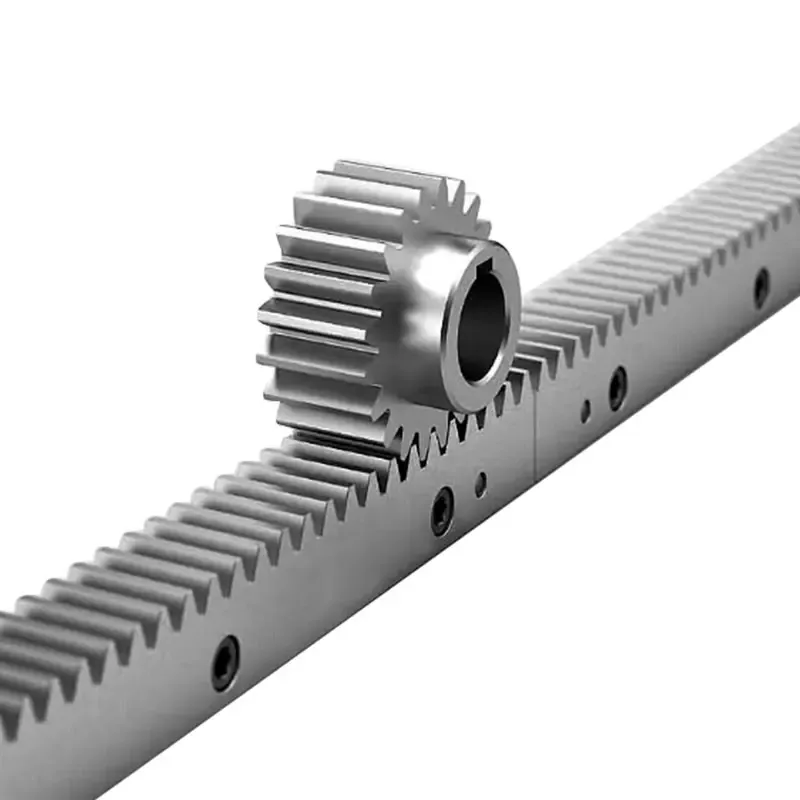

Tooth Profile | Spur Gears, Helical Gears, Bevel Gears |

Module | M0.5, M0.8, M1.0, M1.5,M2.0,M2.5,M3.0...etc |

Teeth Quantity | 10-150 teeth or customized |

Inner Bore | 2-200mm or customized |

Pressure Angle | 20 Degree |

Direction | Left hand or right hand |

Teeth Width | Customized |

Total Thickness | Customized |

Heat Treatment | Gear Teeth Induction Quenching |

| |

Automotive

| Power Steering Rack and Pinion Assembly Steering Gear Rack and Pinion Unit

Steering Rack and Pinion Kit

Rack and Pinion Steering Gear Box |

Industrial Machinery

| Linear Motion Rack and Pinion System Rotary Motion Rack and Pinion Drive

Actuator Rack and Pinion Assembly

Positioning System with Rack and Pinion |

Material Handling

| Crane Hoist Rack and Pinion System Scissor Lift Rack and Pinion Drive

Cargo Elevator Rack and Pinion Assembly

Automated Storage and Retrieval System (ASRS) Rack and Pinion Drive |

Construction

| Scaffolding Rack and Pinion System Elevator Rack and Pinion Drive

Bridge Formwork Rack and Pinion Assembly

Mast Climbing Work Platform Rack and Pinion Drive |

Robotics

| Robotic Arm Rack and Pinion Drive Linear Actuator with Rack and Pinion System

CNC Machine Tool Rack and Pinion Drive

Gantry Robot Rack and Pinion Assembly |

Medical Equipment

| Medical Table Positioning Rack and Pinion System Imaging Equipment Rack and Pinion Drive

Robotic Surgery Rack and Pinion Assembly

Prosthetic Limb Rack and Pinion Drive |

OEM&ODM(Rack Gear)

We can make standard/special Gear andGear Rack according to drawings or samples.

Gear material can be carbon steel,

stainless steel, aluminium, copper, brass

etc.

Tell us your requirements today.1400mm Rack Rail Flexible Racks For Cnc Machine Plastic Helical And Box Pinion Gears Trade Metal Rack Gear

Get a Free Quotation via Us >>> Go

Characteristics of Rack and Pinion

★The tooth surface of the fine-milling rack is processed by fine-milling, and the multiple finishing processes ensure that the tooth surface has small deformation and high consistency.

★The precision of the precision milling rack can reach grade 5, and the precision is high.

★The whole rack is quenched and tempered, all surfaces except the tooth surface are ironed, and the positioning accuracy is high.

★Affordable price, widely used in automation, robotics, automatic welding and other fields.

Food Processing/Sewage treatment plant/Filling Machinery/Transport Equipment/Electronic/Medical Instruments/Glass Machinery/Aircraft Accessories/Ship Manufacturin/Appliance/Auto/Industrial equipment metal stamping hardware parts.

Suzhou Konlida Precision Electronic Co., Ltd. was founded in 2006,Is a focus on Machining Services,Gears, Assembly Service and development manufacturer. Konlida company has25000 square meters of production base, the introduction of domestic and foreign advanced manufacturing equipment more than 50 units, and so on. Mold more than 2000 sets, an annual output of various types of rubber belt 500,000. The main products for the rubber belt series of products, such as coated timing belt, rubber flat belt, rubber haul off belt, PU timing belt, ATM belt, sausage machine belt, printer Belt, and so on.

Konlida company strictly implements IS09001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging equipment, pipe wire and cable traction equipment, food packaging film equipment, wood chopsticks carpentry equipment, and so on.

Q1. Can I have a sample order for Timing Belt?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A:Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity.

Q3. Do you have any MOQ limit for order?

A: Low MOQ, 1-10 pcs for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5: What are the payment terms?

Western Union, Paypal, Ali Secure Pay or T/T (company account and personal account)

Q6.What are your company major products?

Our main products are Sausage Timing Belt ,film pull belt ,rubber belt, transmission belt,triangle V belt etc.

Q7.What about the price?

We try our best to give the competitive price with the high quality.

Company Advantages

specializes in the production and sales of Our company has built a sound service system. It can provide customers with one-stop services with product consultation, professional debugging, skills training, after-sales service.

Our company is committed to providing professional and quality products with affordable prices for customers. Welcome customers in need to contact us, and look forward to establishing a mutually beneficial relationship with you!