Beryllium copper shrapnel has high relaxation resistance and excellent wear resistance. It is also burn resistant and unaffected by radiation. With all these advantages Konlida beryllium copper shrapnel becomes the ideal emc shielding material for computer and electrical design engineers.

Konlida uses beryllium copper material: American Brushwellman imported beryllium copper material, which belongs to high beryllium material (containing beryllium: 1.8-2.0%); there are 2 kinds of materials before heat treatment: C17200-1/4H and C17200-1/2H, Corresponding to the original material hardness: 110-180HV and 175-230HV. Mainly provides 2 choices for stamping materials. After heat treatment, the minimum hardness is above 373HV. In summary: For the end customer, choose 1/4H and 1/2H It has no effect.

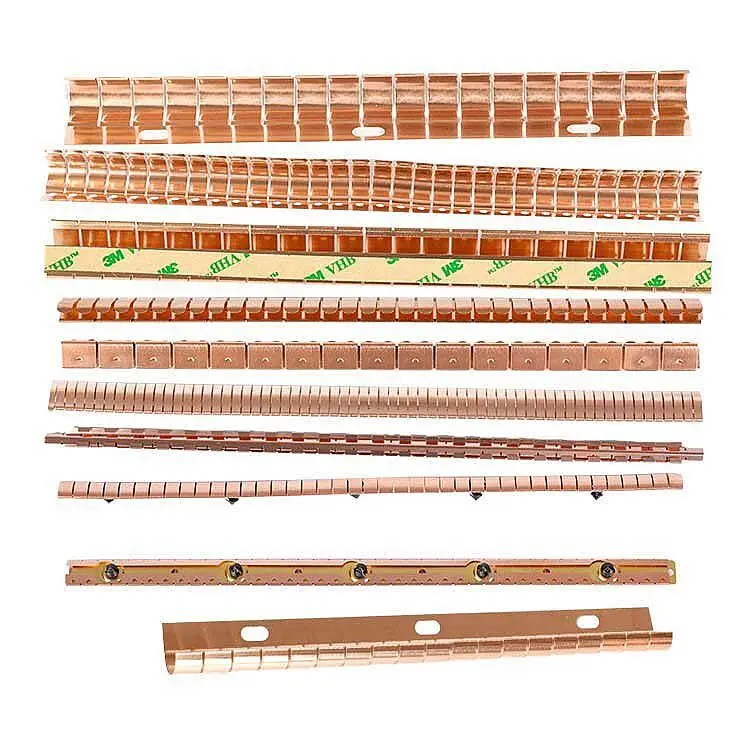

Feature

Non-conductive, double sided, acrylic pressure sensitive adhesive type 3M 9469PC or equivalent, 0.13mm thick, clear colour. Temperature range -40°C to 121°C. Shelf life for 12 months.

Apply at room temperature to a clean, dry surface. Remove any oily residues with rubbing alcohol. Once the gasket is in position, press firmly to achieve a good bond. Repositioning the gasket may impair the effectiveness of the adhesive or damage the strip. 50% of ultimate strength will be achieved after 20 minutes, 90% after 24 hours and 100% after 72 hours. Elevated temperatures may increase ultimate bond strength more quickly.

The 3M tape is moisture, solvent and temperature tolerant and meets MIL standard specifications.

Installation method of metal beryllium copper Shrapnel

1. Slotted installation:

Cut out the holes and slots needed to install the product on the panel. The length of the hole slots is determined by the length of the product.

Take our MB-1116-01 as an example:

Panel thickness: T=1.0MM; the hole spacing is about: 6.6MM; MB-1721-01 corresponds to the panel thickness T=1.50MM;

Other: MB-1216-01, MB-1136-01, MB-1711-01, etc. can also use similar installation methods;

2. Adhesive tape: This method has a good effect and requires a certain amount of pressure.

It is an ideal choice for metal shells and electronic shell shielding strips; the most commonly used: MB-1550-01/1551-01; MB-1500/520/521/540 /541-01, etc.; our company mainly uses 9469 tapes from 3M Company,

conductive tape: 3M9703, etc.;

3. Other installation methods: such as riveting, brazing, clamping, etc.;

4. Rivet fixed type;

5. Welding method;

6. Brazing method;

Application

Beryllium copper has a wide range of applications, such as shielding rooms, chassis doors, cover plates, printed board inserts and integrated circuit shielding, etc.

Advantages of beryllium copper Shrapnel

• Low compression force

• Highest strength copper alloy with high cycle life

• Maximum spring properties

• Excellent conductivity

• Conforms to large gap variations

• Dimensional stability

• Excellent for bi-directional applications

• Wide temperature variation and non-magnetic

• Resistance to stress relaxation

• Easy installation

• Non flammable

• Easy to plate

• Variety of mounting options, sizes and configurations

• RoHS compliant