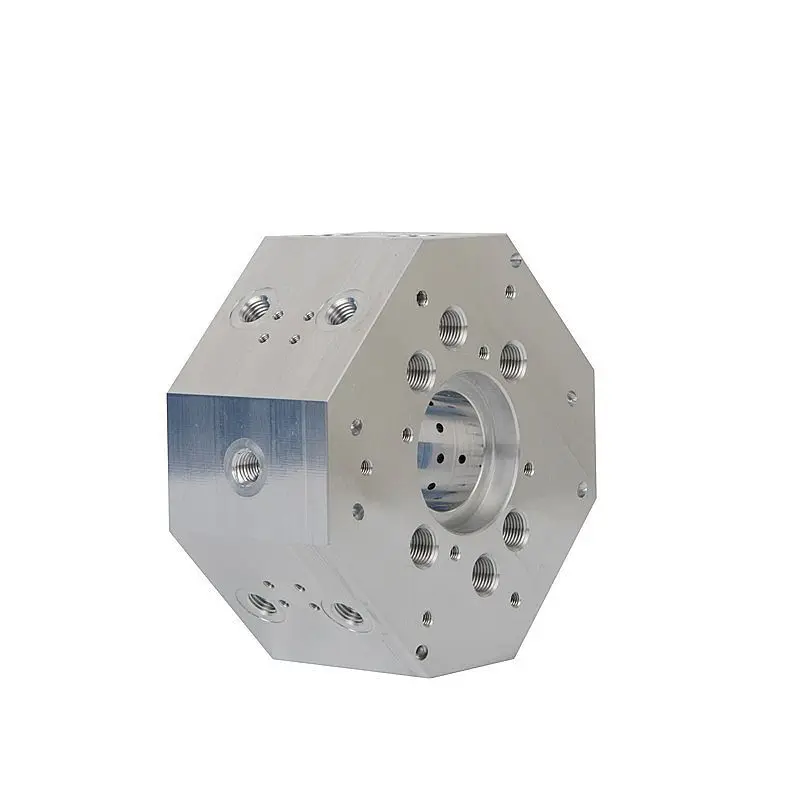

porous valve bodies

Metal & non-metal precision parts

Requirements for porous valve body products: the surface color oxidation, the concentricity of the symmetrical circle on both sides shall be 0.01mm,...

Requirements for porous valve body products: the surface color oxidation, the concentricity of the symmetrical circle on both sides shall be 0.01mm, the perpendicularity shall be 0.02mm, the hole wall finish shall be Ra0.6, and the base plane shall be 0.005mm.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Material: AL7075

Size: 120 * 120 * 75mm

Keywords: valve body, mechanical parts, fixture parts, natural color oxidation

Product Details:

- The porous valve body product is of symmetrical structure. The AL7075 aluminum alloy is selected for CNC processing. The porous valve body is processed with this most powerful alloy material, so that the product has good mechanical properties, excellent corrosion resistance and oxidation resistance, is easy to process, and has excellent wear resistance. The surface of the porous valve body is subject to natural color oxidation treatment as a whole.

Usage:

- Due to its unique structure and performance, the porous valve body is widely used in mechanical equipment, mold parts, fixture parts, automobiles and other fields.

Processing Process:

- senior programming engineers ensure that the concentricity, perpendicularity, hole wall finish, datum plane flatness and the dimension from the hole center to the datum plane are 0.01mm, 0.02mm, Ra0.6, 0.005mm and ± 0.01mm respectively through precision positioning, clamping and 4-axis processing technology.

Typical CNC Parts:

- Housings and enclosures/Brackets/Fixtures for manufacturing/Gears and bearings/Internal mechanical components/Medical instrumentation

Advantages of CNC Machining:

- Precision and repeatability/Tight tolerances/Production-grade materials/Quick-turn parts within 1 day

Our Advantages

- Strong factory: The company was established in 2006, focusing on the R&D and production of electromagnetic shielding/thermal management products, as well as the machining and assembly services of high-quality precision parts. Now it has passed ISO9001 and ISO13485 certification! Reliable quality and competitive price

- Advanced production equipment: DMU/die-casting zinc alloy/FINUC CNC machining center. All equipment is imported from Japan and Germany.

- Complete testing equipment: various precision testing equipment: Japan Sanfeng internal hole meter, altimeter, runout meter, gear testing center, three coordinates. The measuring items include the tooth shape, tooth orientation, pitch, runout, and common normal of the gear. The measuring accuracy can reach ISO1.

- Rich production experience: the company has 30 R&D engineers and 37 core patents. The first time to provide customers with solutions.

- OEM: support customized products with drawings and samples, buyer design, and buyer label service.

- Fast quotation/fast response: 24-hour online service for 7 days, and the quotation will be replied to you within 24 working hours.

- Strict quality: the production is checked at all levels, and the QC fully inspects the delivery, including the test report, to protect your products.

- Fast delivery: more than 300 employees work in shifts 24 hours a day, usually 7-15 working days. The ease of product delivery determines the delivery date.

Keyword:CNC Machining Factory/CNC Lathe Services/Precision Machining Cheap China large factory company precision high speed titanium plastic aluminum steel brass metal aerospace 4 5Axis cnc lathe turning milling milled grinding cutting machining machined services for Car medical aerospace motorcycle auto aircraft robotics parts

Services:

- CNC machining (turning/milling)

- Sheet metal manufacturing

- Injection molding service

- 3D printing service

CNC Machining Material:

- Aluminum: AL 6061-T6, 6063, 7075-T etc

- Stainless Steel: 303, 304, 316L,17-4(SUS630) etc

- Steel: 4140, Q235, Q345B, 20#, 45# etc.

- Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc

- Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc

- Copper,Bronze, Magnesium Alloy, Delrin, POM, Acrylic, PC, etc.

Surface Finishing:

- Sandblasting, Anodize Color, Blackenning, Zinc/Nickl Plating, Polish,

- Power Coating, Passivation PVD, Titanium Plating, Electrogalvanizing,

- Electroplating Chromium, Electrophoresis, QPQ(Quench-Polish-Quench),

- Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc.

Main Equipment:

- CNC Machining Center(Milling), CNC Lathe, Grinding Machining,

- Cylindrical Grinder Machine, Drilling Machine, Laser Cutting Machine,etc.

Drawing Format:

- STEP, STP, GIS, CAD, PDF, DWG, DXF etc or samples.

Tolerance:+/-0.01mm ~ +/-0.05mm

Surface Roughness:Ra 0.1~3.2

Inspection:

- Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM

- Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge

Capacity:

- CNC Turning Work Range: φ0.5mm-φ150mm*300mm

- CNC Milling Work Range: 510mm*1020mm*500mm

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

GET IN TOUCH WITH US

Mob:+86 189 1365 7912

Tel: +86 0512-66563293-8010

Email: sales78@konlidacn.com

Address: 88 Dongxin Road, Xukou Town, Wuzhong District, Suzhou City, Jiangsu Province, China

ABOUT US

Copyright © 2025 KONLIDA | Sitemap

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.