Precision Die Cutting Manufacturer Shielding and Conductive by

EMI FOF conductive foam -high performance Shielding effectiveness different types of gasket

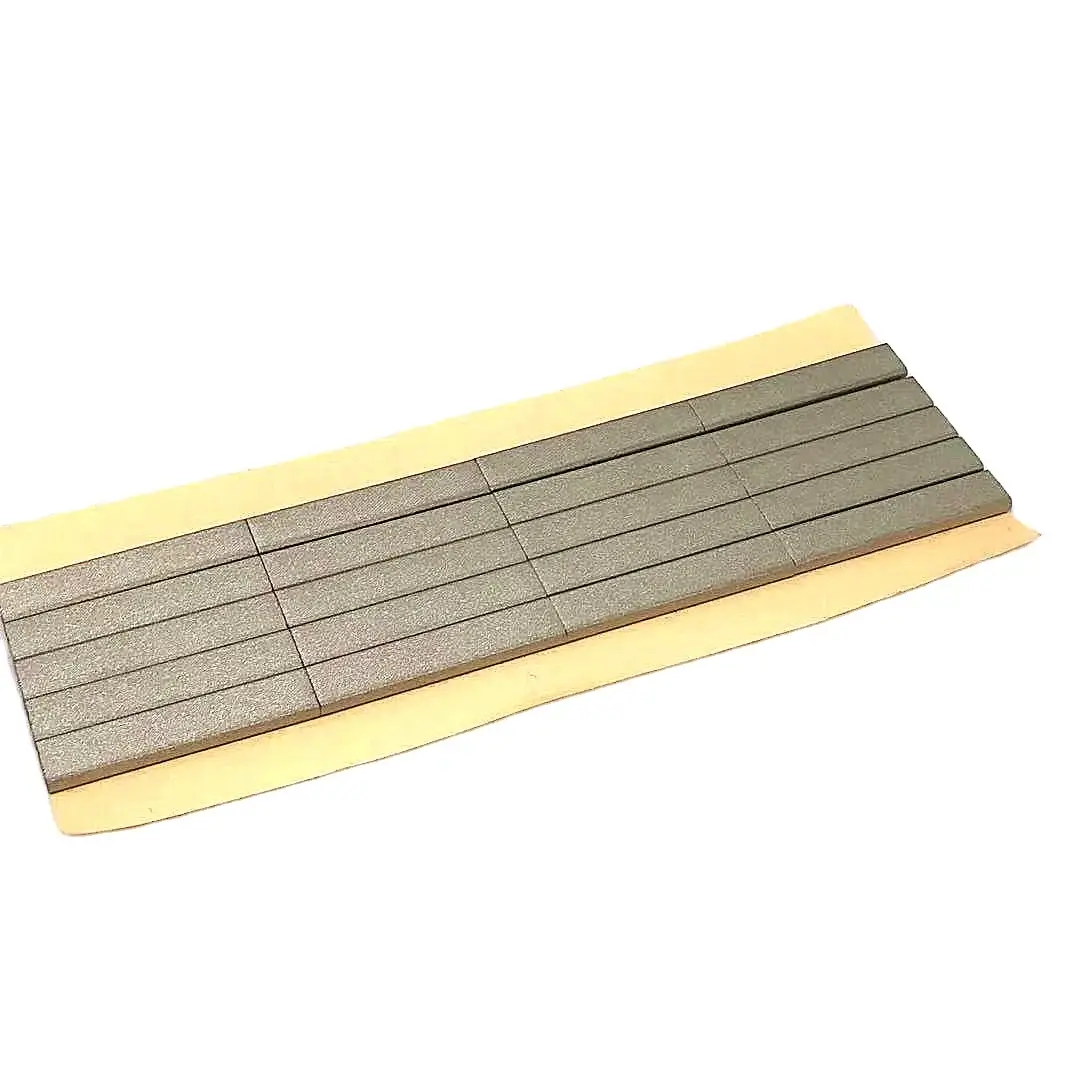

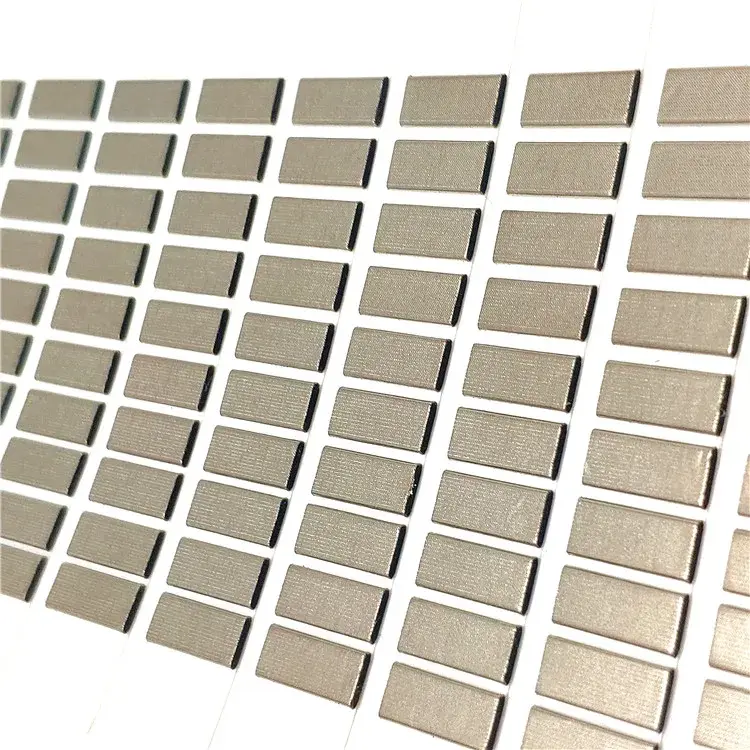

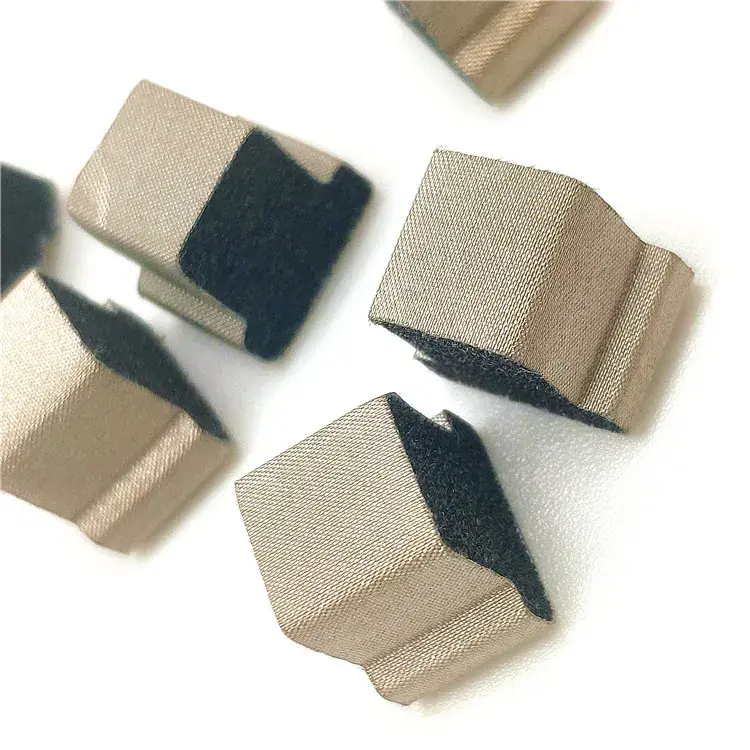

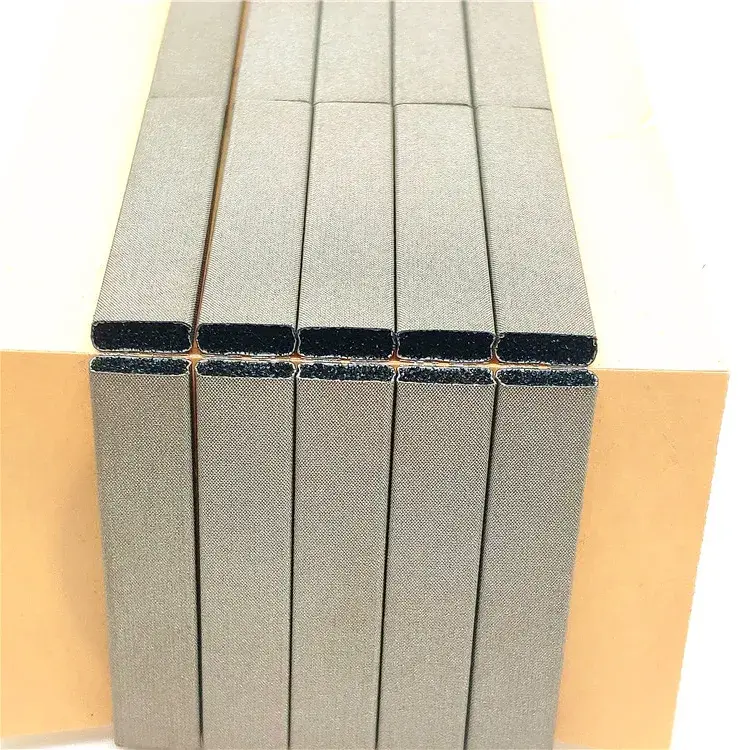

EMI FOF conductive foam is composed of conductive cloth wrapped with conductive foam . There is a hot melt adhesive between conductive cloth and conductive foam . The hot melt adhesive binds conductive cloth and conductive foam into one structure. On the outer side of conductive cloth, there is a conductive adhesive for fixing conductive cloth foam sliver.

The shape, specification and color of EMI FOF conductive foam can be customized.Its color and resistance mainly depend on conductive cloth, its thickness and density mainly depend on foam.

| Surface Resistance: | ≤0.03Ω/inch |

| Shielding Effect: | 60dB~90dB/30MHz~3GHz |

| Heat-resisting Temperature: | - 40 ℃ - 120 ℃ |

| Frictional Resistance: | above 400,000 times ASTND4966-98 |

| Metal Layer Binding Force: | more than 4 AATCC TM8-2001 |

| Tensile Strength: | 1.3 (kg / 25 mm) |

| Initial Adhesion: | 1200 g / 25 mm |

| Maintain Adhesion: | 4000 Min/inch |

| Fire Rating : | UL94V0. 94 (HF - 1) |

Conductive foam can be divided into Conductive foam can be divided into ordinary conductive foam, nickel-plated copper conductive foam, gold-plated conductive foam, carbon-coated conductive foam, tin-plated conductive foam, conductive aluminum foil foam, conductive copper foil foam, all-round conductive foam , SMT conductive foam, I / O conductive foam pad, etc.

Conductive foam are widely used in the plasma TV, LCD monitor, LCD TV, mobile phone, Laptop PC, Desktop PC, PDA, MP4, communications cabinets, medical instruments and other electronic products.

Conductive foam is also widely used in PDP TV, LCD display, notebook computer, MP3, communication cabinet, medical equipment and other electronic fields, specifically for conductive parts in electronic products, such as antenna modules, tail plugs At the office, at the earpiece, at the seal of the chassis, etc.

Its main function is shielding and conduction.

OEM and ODM services are available in a variety of sizes and shapes, depending on the customer's needs.

Development of electromagnetic shielding under the requirement of resistance and pressure synchronization.

Use testing equipment to scientifically verify the products.

Q1: Can I get free Conductive Foam sample?

A1:Yes, Konlida is glad to offer 10 pcs free samples as long as we have stock,however, for customized samples , Konlida may need to charge some basic cost of the sample,but samples fee will be deducted from the initial bulk order.

Q2:Are you a factory or a trading company?

A2: We are a professional manufacturer of EMI products for over 13 years.

Q3 : How to ship Conductive Foam ?

A3: Konlida usually send small packages by express companies, which is fast, like DHL, UPS, and FedEx,we also can ship the packages under customer’s account.For bulk order, Konlida usually ship by sea,the delivery cost is cheaper

Q4: Can I get the customized Conductive Foam sample?

A4: Yes, we can offer different thickness and different thermal conductivity for you and give you best solution.If you do not have clear idea, you can inform us the product application and the power of your product, we can provide right products for you.

Konlida is an ISO9001:2008, ISO13485:2016 quality system certification company. Since its establishment in 2006, we have provided EMI, EMC, thermal management, precision die-cutting, ultra-precision metal and non-metal parts for customers in the electronics, communications, medical, automotive and other industries.

We have the ability to provide customers with everything from solutions to material selection to process implementation, complete test data, and more. Even difficult design issues can be solved.

Company Advantages

· Precision die cutting Manufacturer follows advanced techniques to eliminate waste.

· The product promises high quality and long service life.

· This product is over and above our rival's product, and yet we're able to sell it at the same price.

Company Features

· is dedicated to producing best Precision die cutting Manufacturer and expanding wider market.

· now has been developed into a famous brand named that is specialized in producing Precision die cutting Manufacturer.

· By improving the quality of service, brand will pay more attention to its culture establishment. Call!

Application of the Product

Precision die cutting Manufacturer of can be used in different industries to meet the needs of customers in different fields.

We will communicate with our customers to understand their situations and provide them with effective solutions.

ABOUT US